Robotics is transforming manufacturing at a pace few could have predicted. From AI-powered automation to humanoid robots entering factory floors, the era of how robotics are changing manufacturing has arrived. Once locked into rigid assembly lines, factories are now adapting flexible, intelligent systems that prioritize efficiency, safety, and sustainability. In this article, we’ll explore key trends shaping the future of manufacturing—giving you insight into where the industry is headed in 2025 and beyond.

1. AI-Enhanced Robotics: Smarter, Adaptive, and Intent-Driven

Modern robotics is no longer confined to repetitive tasks. Artificial intelligence (AI) is supercharging robots with data-driven decision-making abilities. The International Federation of Robotics highlights three AI-driven advancements:

- Analytical AI helps robots analyze sensor data to adjust actions in real time.

- Physical AI enables virtual training simulations, allowing robots to learn tasks without direct programming.

- Generative AI—an upcoming leap—could enable robots to generate actions or strategies like a “ChatGPT moment” for physical robotics.

This shift means factories can handle varied tasks, optimize operations, and adapt to changing production needs—blurring the line between programming and learning.

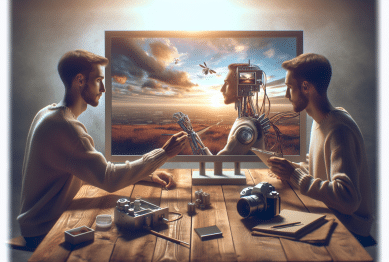

2. Collaborative Robots (Cobots): Efficiency Meets Human Synergy

Cobots—designed to work alongside humans—are redefining teamwork on the factory floor. A recent survey shows that cobots can reduce assembly times by 30% and boost quality by 15%, while AI-driven autonomy cuts errors by 30% and energy use by 20%.

Their rise brings immense benefits:

- Greater workplace safety, especially in hazardous environments.

- Flexibility for dynamic production lines.

- Skill evolution, empowering human workers to manage higher-level tasks.

Cobots are part of how robotics are changing manufacturing—creating safer, smarter, and more cooperative work systems.

3. Robotics-as-a-Service (RaaS): Democratizing Automation

High upfront cost and technical demands have long barred smaller manufacturers from adopting robotics. But now, Robotics-as-a-Service (RaaS) is changing that.

- Subscriptions allow access to turnkey robotics systems—hardware, software, sensors, maintenance—all bundled into operating costs.

- This model lowers entry barriers and makes scaling automation more viable for SMBs.

RaaS illustrates a new direction in how robotics are changing manufacturing—making automation more accessible, flexible, and affordable.

4. Virtual Manufacturing, Digital Twins, and Vision-Guided Robots

Robotics integration is now backed by virtual environments and precision control:

- Virtual manufacturing and digital twins simulate entire production workflows, enabling optimized planning and reduced downtime.

- Vision-guided robots (VGRs) use cameras and feedback loops to identify and manipulate parts dynamically—boosting adaptability and efficiency.

These breakthroughs reveal how robotics are changing manufacturing by enabling smarter, planned, and responsive automation—cutting costs and industrial guesswork.

5. Humanoid Robots: The New Frontier—but Not Without Limits

The concept of robots in human form is no longer sci-fi. Reports expect up to 1 million industrial humanoid robots by 2030, with companies such as Hyundai (Atlas) and Agility Robotics deploying early models.

Humanoid robots offer:

- Adaptability to human-designed environments.

- Potential for handling irregular tasks.

However, challenges remain—safety, high cost, autonomy, and ethical concerns about job displacement.

Humanoids represent the bold edge of how robotics are changing manufacturing—one that holds promise and provokes debate.

6. Tackling Labor Shortages with Robotics and Training

Manufacturing faces a labor shortage that robotics can help alleviate. U.S. robotics adoption is escalating as companies seek automation to maintain productivity. Initiatives like tariffs, training programs, and expansion efforts by firms like Hyundai underscore this trend.

Training the workforce for automation isn’t just about survival—it’s a pathway to new, higher-paying technical roles in robotics maintenance and programming.

7. Sustainable Production with Robotics

Sustainability is no longer optional. Robotics contribute significantly to greener manufacturing:

- Precise automation reduces waste and ensures product consistency.

- Robotics in green sectors—like solar panel assembly or EV battery production—are integral scaling tools.

Manufacturers increasingly rely on robotics to align efficiency with environmental stewardship.

8. Swarm Robotics & Reconfigurable Modular Systems

The future of adaptability lies in robots that self-adjust:

- Swarm robotics uses multiple autonomous units working together like natural colonies—ideal for complex tasks or variable environments.

- Self-reconfiguring modular robots can change form to fit different tasks, environments, or to repair themselves.

Such systems embody adaptability and resilience—highlighting how robotics are changing manufacturing with dynamic, scalable capabilities.

9. Industrial AR: Smarter Human-Robot Collaboration

Augmented reality (AR) is strengthening human and robotic collaboration:

- AR provides real-time guidance during assembly, maintenance, and training—reducing errors and boosting efficiency.

As robotics evolve, integrating AR ensures that human workers remain informed, connected, and safe.

10. Real Impact from Artificial Intelligence and Automation

AI platforms now enable manufacturing to evolve beyond automation—it’s becoming integrated intelligence:

- Robots can analyze operations, self-optimize, and respond without manual inputs.

- This intelligent integration is pushing productivity, quality, and flexibility across industries.

AI-driven robotics represents the modern frontier of how robotics are changing manufacturing—making production smarter and adaptable.

Practical Guide: Implementing Robotics in Manufacturing Environments

- Start Small: Try cobots or RaaS for low-risk entry into automation.

- Leverage AI Tools: Adopt vision systems or virtual twin software to streamline processes.

- Train Teams: Invest in robotics maintenance and AI literacy for longevity.

- Plan for Sustainability: Use robotics to reduce waste, energy use, and carbon footprint.

- Evaluate Humanoid Potential: Monitor developments and assess fit for human-centric tasks.

This step-by-step approach helps businesses embrace how robotics are changing manufacturing thoughtfully and effectively.

Conclusion

Robotics is reshaping manufacturing in profound ways—infusing intelligence, sustainability, adaptability, and efficiency into factories. From AI-guided systems to humanoid versatility, each trend points toward a future that is both innovative and human-centric.

Understanding how robotics are changing manufacturing helps industry leaders anticipate, adapt, and lead sweeping changes. Whether through smarter factories or upskilled workforce, the robots of today are laying the foundation for manufacturing of tomorrow.

References

- Dassault Systèmes. Modular Robots and Robotics as a Service (RaaS) https://www.3ds.com/manufacturing/manufacturing-workforce/future-of-robotics-in-manufacturing?utm_source=chatgpt.com

- International Federation of Robotics. Top 5 Global Robotics Trends 2025 https://ifr.org/ifr-press-releases/news/top-5-global-robotics-trends-2025?utm_source=chatgpt.com

- MDPI. Collaborative Robots Performance Statistics https://www.mdpi.com/2227-9717/13/3/832?utm_source=chatgpt.com

The Evolution of Online Education Platforms

The Evolution of Online Education Platforms